Copyright © 2011-24 Helical Pile World, LLC. All Rights Reserved.

Home | Engineers | Manufacturers | Installation Contractors | News | Technical Advisors | Contact Us

Helical piles have been around since the mid-1800s and have supported lighthouses, telecommunications, roads, rails, bridges, and more. They are often a first choice for builders and construction project planners because they install quickly with no excavation required. As a foundational technology, helical piles screw into the soil much like a common screw installs into wood, but on a much larger scale. However, all so-called helical piles are not created equally, and here is why.

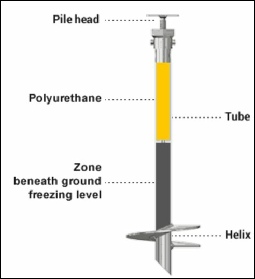

A helical pile has three distinct parts: The shaft, the helix, and the attachment or pile head. Through exhaustive testing (see helical pile calculations) [https://www.goliathtechpiles.com/engineers-inspectors] by the pioneers of helical pile technology, it was proven that to be certain of the capacity numbers (i.e., tension, compression) of a helical pile, it must have a true helix design. This requires the helix to have a straight leading edge and a straight trailing edge, and both must be parallel at the front and at the back as they start to pitch. Additionally, the pitch must be a true three-inch pitch. This means that for each revolution (or turn) of the helical pile, it descends into the ground three inches. A duck-bill “helix” is not a true helix.

For instance, a five-inch pitch will go in the ground faster per revolution, yet we cannot rely on the torque during installation-to-capacity correlation, which is the fundamental basis of helical piles. Helices (plural for “helix”) manufactured by GoliathTech [https://www.goliathtechpiles.com/] which is certified ISO 9001:2015 are stamped on a precision machine with a precision mold so that every single one of our helices has the exact shape. As we install our helical piles with our designated installation machinery, we apply crowd to the top of the pile so as it turns into the ground, it does not “spin out”, essentially loosening the soil. For example, when you install a screw into wood, if you do not “push” or apply a downward pressure (crowd) on the screw, it could potentially strip the hole and the screw would become useless. Helical piles work the same way in the soil.

There are two ways to get more capacity from a helical pile with a true helix design: One is to go deeper, in order to reach “better” or firmer soil that would increase the pile installation torque and therefore its capacity. The other is to use a larger helix, essentially increasing the helices’ contact on the soil. It is a fact that while a larger helix will give more capacity at the same soil depth, in some cases it is not the best option. For instance, it would be more advantageous to use a smaller helix on a project built on very rocky soil. The larger helix would be ideal for a project built on wetter, softer soil.

Whatever way you look at it, using a helical pile with a true helix design will give you the capacity numbers you require to get your project done right the first time.

About GoliathTech:

GoliathTech is a multinational manufacturer of helical piles. For more than 15 years, we have combined strength with know-how to offer you the best piling solution to support your project. Manufacturer and installer of helical screw piles, GoliathTech never stops innovating so that you may benefit from unequalled quality products and services. Our network of hundreds of certified installers does more than merely carry out simple tasks. They put their vast experience to work to guarantee optimal anchoring of each pile.

GoliathTech Incorporated

175B, rue Péladeau

Magog, Québec (Canada) J1X 5G9

Toll Free: 1.855.743.4777

info@goliathtechpiles.com

Why All Helical Piles Aren’t Made the Same

March 2021