Copyright © 2011-26 Helical Pile World, LLC. All Rights Reserved.

Home | Engineers | Manufacturers | Installation Contractors | News | Contact Us

Helicals for Environmental Remediation: Clean and Green

The New Jersey Department of Environmental Protection (NJDEP) was established on April 22, 1970, America’s first official Earth Day. New Jersey was one of the leaders among the states in recognizing the importance of safeguarding and enhancing not only New Jersey’s air, water, a nd land, but also the health of its residents. The state boasts the third longest stretch of continuous beaches, an asset exceeded only by Florida and California. Tourism, the third largest industry in the state, relies on a pristine environment to keep the beaches crowded throughout the summer.

nd land, but also the health of its residents. The state boasts the third longest stretch of continuous beaches, an asset exceeded only by Florida and California. Tourism, the third largest industry in the state, relies on a pristine environment to keep the beaches crowded throughout the summer.

Like many other Northeast states, New Jersey’s economy historically relied on agriculture, manufacturing, energy production, and other polluting industries that were much less friendly to the environment. New  Jersey is still home to several superfund sites, but the NJDEP has aggressively worked to minimize the impact of past practices. In recent years, helicals have played their part in helping the state maintain its hard-earned reputation as “clean and green” for residents and visitors alike.

Jersey is still home to several superfund sites, but the NJDEP has aggressively worked to minimize the impact of past practices. In recent years, helicals have played their part in helping the state maintain its hard-earned reputation as “clean and green” for residents and visitors alike.

As in many areas, oil was once popular as a home-heating source, replacing coal. Natural gas came along as an even cleaner, more convenient, replacement for oil. However, many homeowners simply abandoned the old oil tanks when switching to gas, leaving the tanks in the ground to eventually rust out and leach the leftover oil into the soil. For over a decade, through the 1990s, Danbro installers were busy supporting residences on pilings, while remediation contractors removed and replaced the contaminated soils. Residential work has slowed over the years, but commercial, industrial, and government work continues. Titan Shoring Contractors, who specialize in this type of work, recently completed a commercial project (with governmental spillover) which illustrates why helicals are still a favorite of Environmental Remediation contractors. Click to See Environmental Remediation Case Histories

remediation contractors removed and replaced the contaminated soils. Residential work has slowed over the years, but commercial, industrial, and government work continues. Titan Shoring Contractors, who specialize in this type of work, recently completed a commercial project (with governmental spillover) which illustrates why helicals are still a favorite of Environmental Remediation contractors. Click to See Environmental Remediation Case Histories

The site of the Tomassello Auto Center in Ventnor, NJ originally opened as a fuel station in 1921. Chris Tomassello bought the business in 1953, adding mechanic services until 1987, when he stopped pumping gas. The tanks remained in the ground until 1996, when he was informed by the state that the tanks needed to be removed. At the time the tanks were removed, there was only limited soil remediation and the site was to be monitored. After twenty years, “the goalposts were moved”, according to Chris, “and now we had to remediate the whole site.” Chris acknowledged that grants from the state largely  mitigated the expense for earlier work as well as this final clean-up.

mitigated the expense for earlier work as well as this final clean-up.

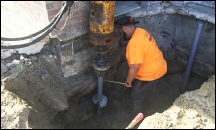

Calmar Associates, an engineering and remediation company, was called in. A Delineation Survey was conducted by doing soil borings horizontally and vertically to determine the width and depth of the contamination. The affected area stretched from the middle of Little Rock Street to a point 15’ into the front of the garage. Although the job included the Municipality (the street work,) it was otherwise straight forward, except for the work underneath the building on the property. The concrete in the drive and asphalt in the street were demoed and the soil was remediated. However, the garage and office areas needed to be temporarily supported, leaving enough room for soil excavation and remediation to take place. A high-water table (encountered at 5.5’) required dewatering during the remediation process. This required the helicals to go deep enough (20’ to 25’) to leave enough headroom (10’) to allow for the work to proceed while providing enough stability to support the exposed foundation.

leave enough headroom (10’) to allow for the work to proceed while providing enough stability to support the exposed foundation.

Higher capacity piles were required to penetrate the gravel/sand mix on the site. IDEAL 2 7/8” pipe piles are manufactured from 80 KSI steel, with integral forged couplings, and come with two or three bolt connections. Therefore, they could provide enough torque to penetrate the gravel/sand mix on the site. Helicals are normally used to provide a deep foundation when low blow count soils are encountered. However, this is often not the case in environmental remediations. The strength and high torque values of IDEAL piles were necessary to provide sufficient torque to  penetrate the high blow count material and resist buckling from the temporarily unsupported exposed shaft. Click to See Titan's Environmental Remediation Project

penetrate the high blow count material and resist buckling from the temporarily unsupported exposed shaft. Click to See Titan's Environmental Remediation Project

“We do a lot of this work,” stated Kevin Pendergast of Titan, “and the helicals make it possible. The IDEAL piles make a difference. These are crowded sites, so we need to use a small excavator to keep out of the way of the GC and other Subs. The helicals provide the temporary support needed to make the remediation under these structures work. We couldn’t do it any other way,” Kevin concluded. John Marion from Calmar Associates confirmed Kevin’s assessment on the indispensability of the helicals and complimented his Sub. “Titan does a nice job for us. Staging is also a big part of the process and Kevin gets here when we need him, so we can stay on schedule,” he concluded.

In the last two decades, helicals have proved themselves to be indispensable in this line of work and have helped New Jersey and other entities to stay clean and green!

by Pat Haffert

Danbro Vice President

October, 2021