Copyright © 2011-24 Helical Pile World, LLC. All Rights Reserved.

Home | Engineers | Manufacturers | Installation Contractors | News | Technical Advisors | Contact Us

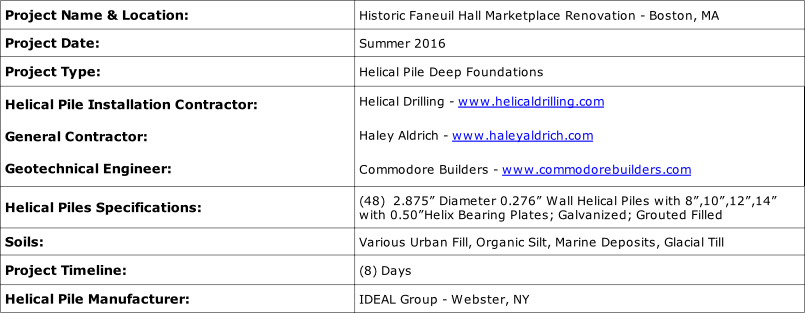

IDEAL Group Teams with Helical Drilling to Install (48) Deep Foundation Helical Piles as Part of the Renovation of Historic Faneuil Hall Marketplace in Boston

Summer, 2016

IDEAL Foundation Systems

999 Picture Parkway

Webster, NY 14580

800-789-4810

Introduction

The project was part of a revitalization of Boston’s historic Faneuil Hall Marketplace, which is located near the City’s original coastline area that was filled in the 17th and 18th centuries to increase waterfront real estate. The revitalization project included replacing an existing 1970’s structure with a new, one-story, retail glass pavilion adjacent to Quincy Market. The structural column loads ranged from about 30 to 60 kips.

Challenges

The work was to be performed in high traffic historic tourist area with limited construction access. Difficult subsurface soil conditions that are common along Boston’s reclaimed waterfront posed another challenge. Subsurface soil conditions generally consisted of 9 to 14 feet of unsuitable urban fill (soil mixed with miscellaneous man-made debris) over up to 5 feet of soft organic silt, over thick natural marine deposits (clay, silt, sand), overlying glacial till. The upper portion of the marine layer was relatively stiff/ dense and became softer with depth. Glacial till was approximately 60- to 70-feet-deep. Remnants of previous structures, such as buried timber wharfs, were present in the fill to further complicate the already challenging subsurface conditions. Groundwater was encountered at 13 to 14 feet below the ground surface. Excavation, disposal, and replacement of the unsuitable fill and organic layers was deemed impractical due to premium costs associated with off-site soil disposal, excavation dewatering, and importing large quantities of structural fill.

Solution

The project team explored several piling options in lieu of excavation/ replacement, including driven timber piles, drilled micropiles, drilled shafts, ductile iron piles, and helical piles. Driven timber piles were economically viable but were eliminated from consideration due to access issues and noise/vibration concerns. Drilled micropiles and drilled shafts both offered low-noise and low-vibration solutions, but were too expensive. Ductile iron piles and helical piles were both appealing options due to ease-of-access, low vibration, and relatively low cost. Helical piles were more economical that other low noise/vibration piles such as drilled micropiles and drilled shafts and they also eliminated the need to export/ import large quantities of fill. The team ultimately selected helical piles as the most suitable and cost-effective piling option and the final pile design was performed by Helical Drilling. The helical piles, from IDEAL Group, were designed to derive end-bearing capacity in the glacial till layer below the fill, organic silt, and marine layers.

Pile Installation

Prior to the installation of production piles, the General Contractor pre-excavated pile locations to remove potential obstructions, including timbers and granite blocks. Pre-excavation proved to be worthwhile as all 48 piles were successfully installed at their planned locations with allowable compression loads of 48 kips. Upon completion, all helical piles were cutoff to their specified elevation and the interior of the pipe shaft was filled with neat cement grout to provide additional corrosion protection.

Quality Assurance and Control

Helical Drilling had a site crew which included a full-time Quality Control person to oversee pile testing and installation. A full-scale compression load test was successfully performed on a test pile that was loaded to 200% of the design capacity. The test results showed deflection of less than ½-inch at design capacity and less than ½-inch of net deflection upon completion of the test. 48 piles were installed over 8 days (including mobilization and load testing) with minimal noise, no vibration, no spoils removed, and no dewatering.